- Home

- Material Jetting

Material Jetting: Innovative Additive Manufacturing Process for High-Quality Products

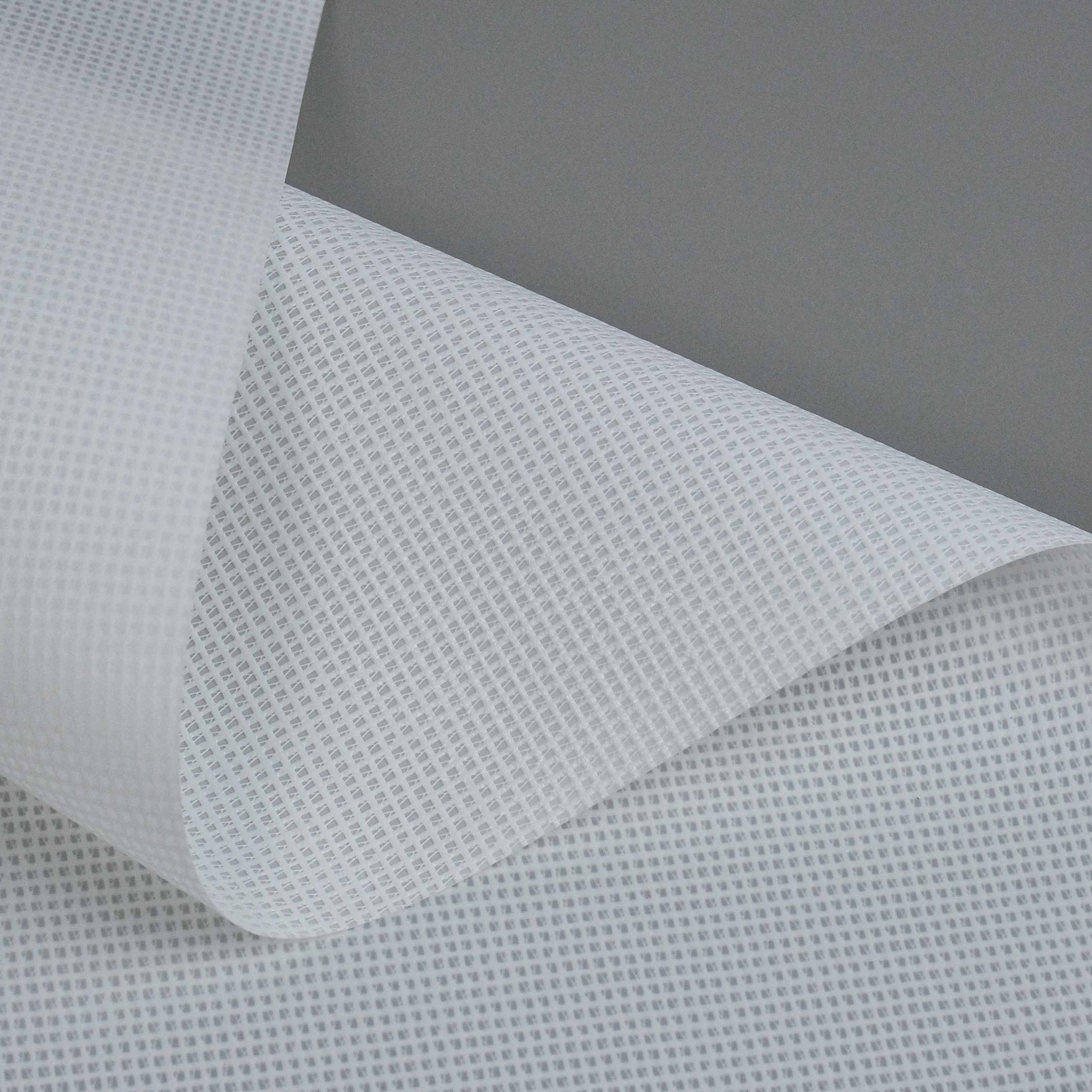

Introducing Best – the revolutionary product by ZheJiang TianXing Technical Textiles Co., Ltd., a leading manufacturer, supplier, and factory in the textile industry. Best is an innovative material jetting technology that is set to redefine the standards of fabric manufacturing.

Material jetting involves the process of accurately depositing layers of material to create high-quality textiles with exceptional precision and detailing. With Best, ZheJiang TianXing Technical Textiles Co., Ltd. takes this technique to new heights, ensuring superior product outcomes and unparalleled customer satisfaction.

This cutting-edge technology enables us to produce textiles with advanced features, such as enhanced durability, breathability, and flexibility. Best allows for the creation of intricate patterns, textures, and designs, unleashing limitless possibilities for the fashion, interior design, and industrial sectors.

With our commitment to excellence and continuous innovation, ZheJiang TianXing Technical Textiles Co., Ltd. brings you Best – the epitome of quality and performance in material jetting technology. Experience the future of textile manufacturing with Best and witness our unwavering dedication to delivering the very best textiles to our valued customers.

ZheJiang TianXing Technical Textiles Co., Ltd.

Company News

Related News

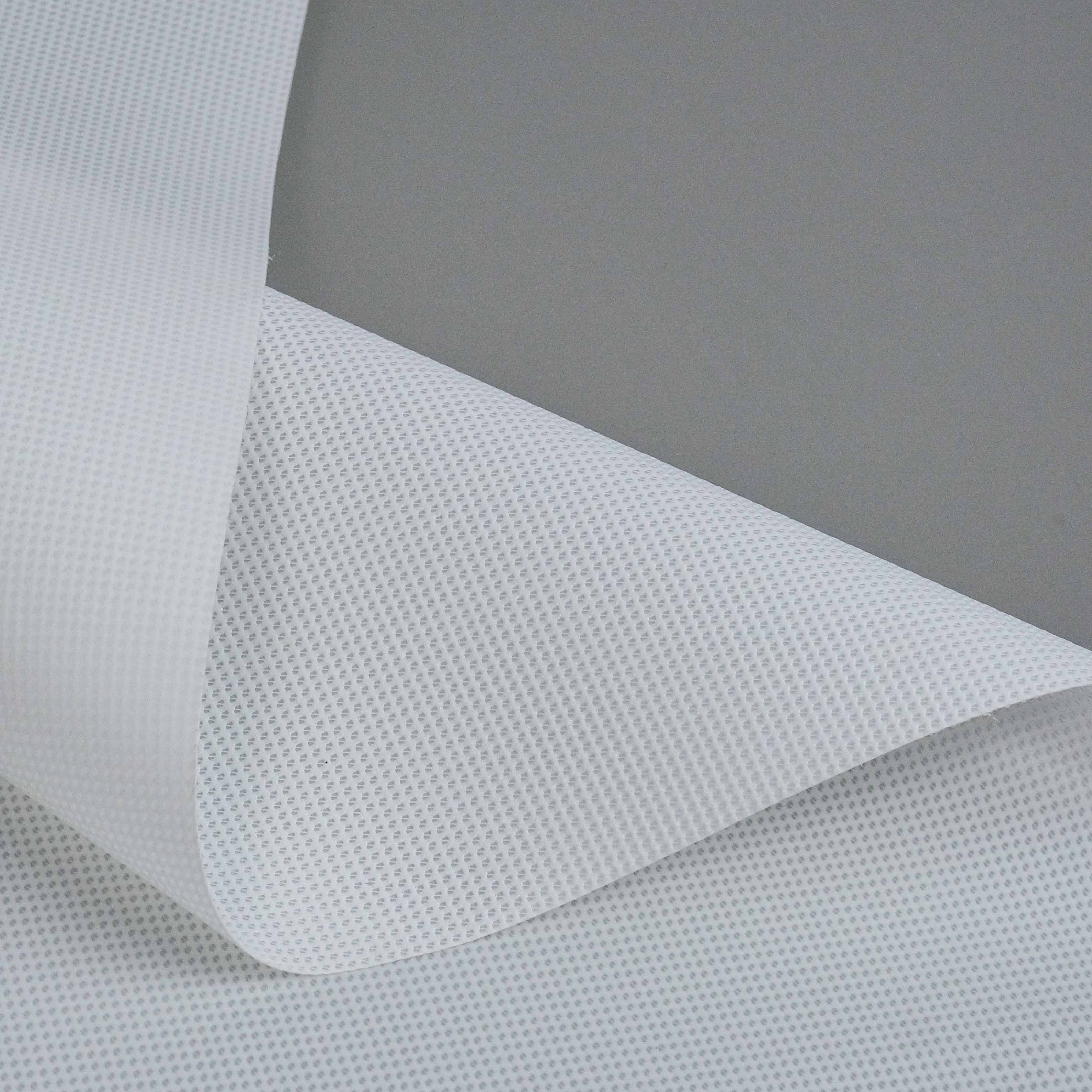

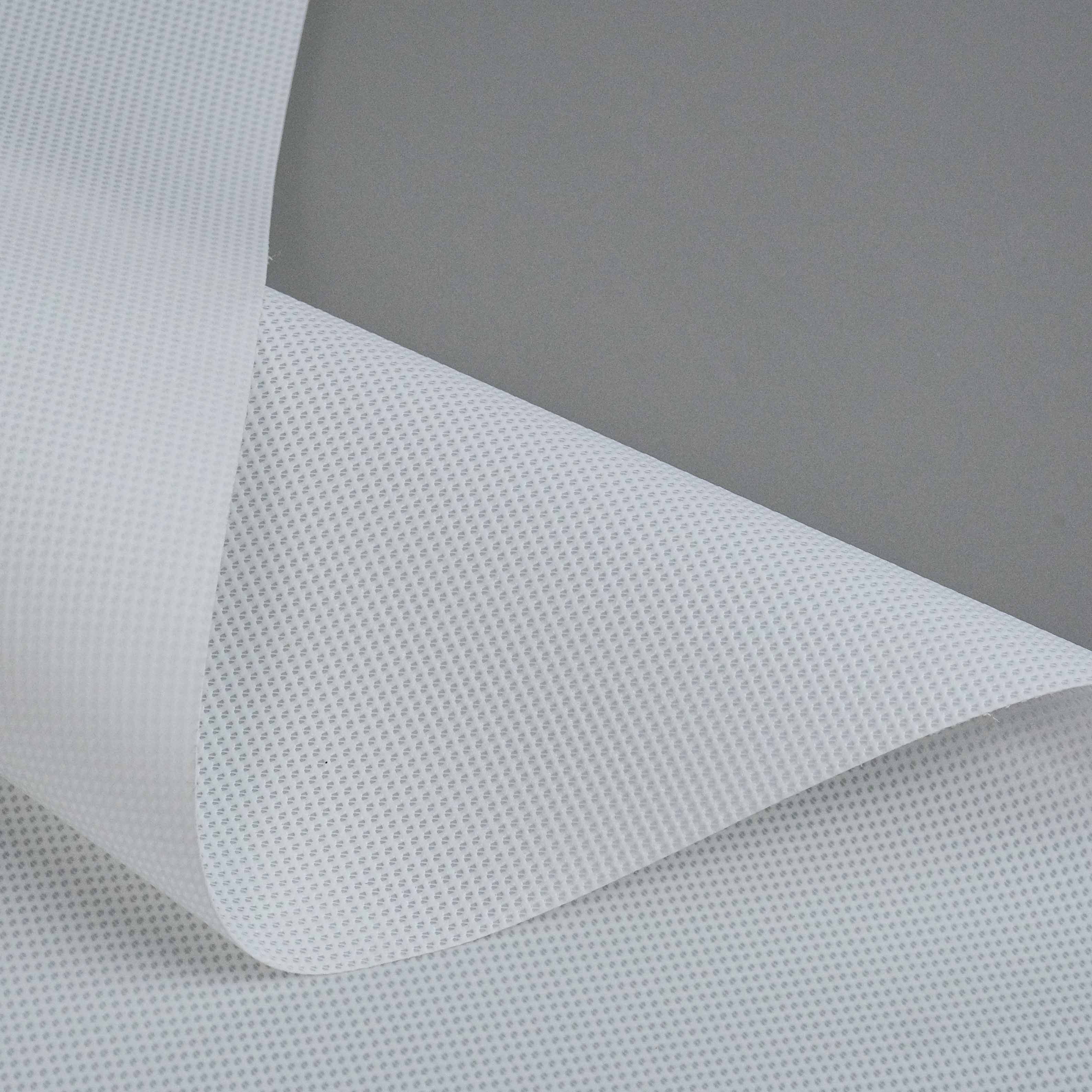

PVC Coated Backing Liner Fabric Mesh For Printing

Get high-quality PVC coated backing liner fabric mesh for printing from our factory. Our product ensures superior print results. Order now!

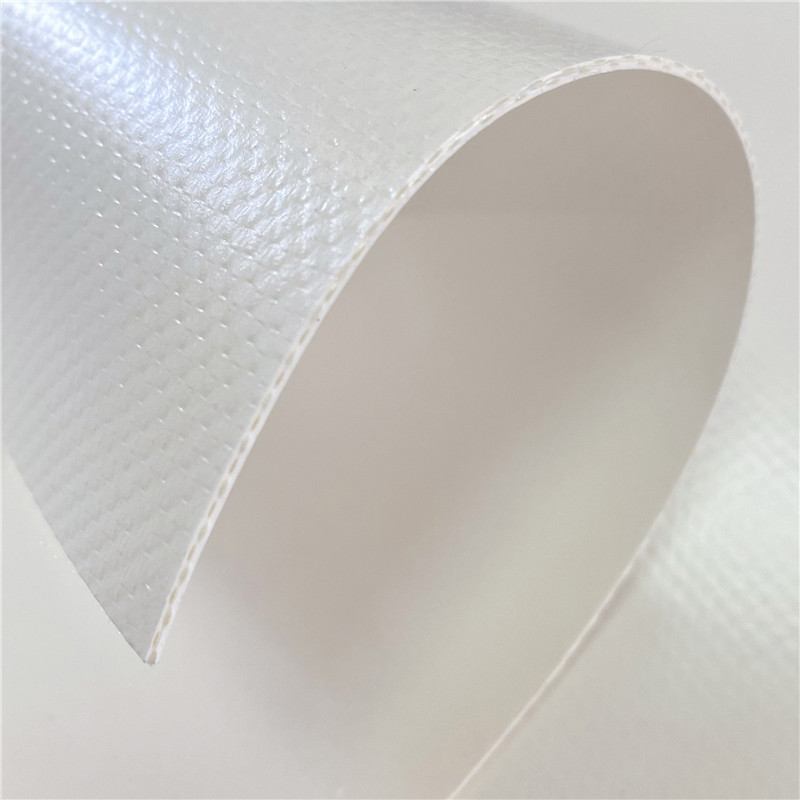

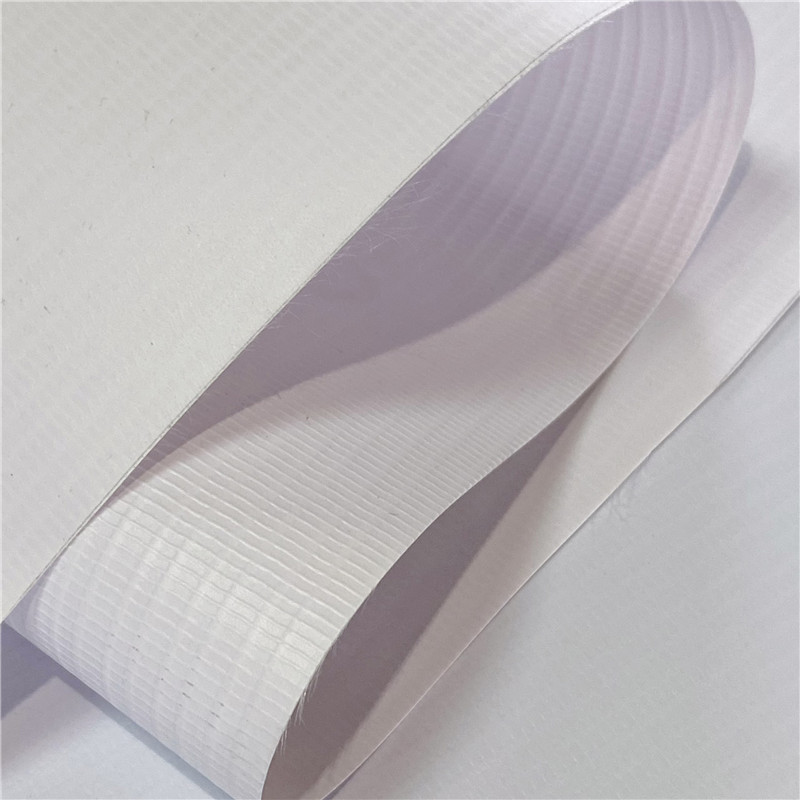

Tarpaulin900-Panama Weaving

Discover top-quality Tarpaulin900-Panama Weaving products at our factory. Indulge in durable and environmentally-friendly solutions. Order now!

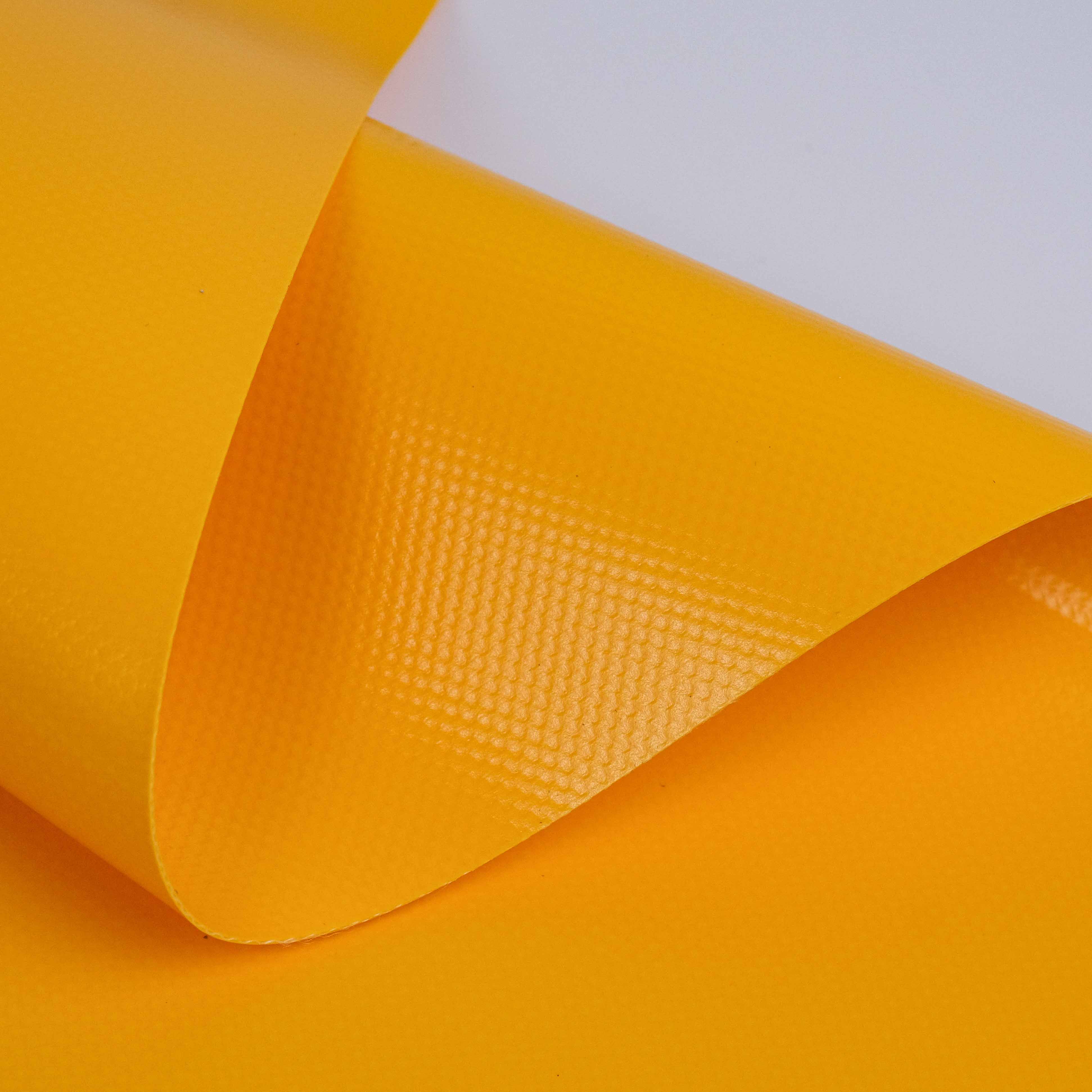

Laminated Glossy Frontlit And Backlit PVC Flex Banner

Discover premium quality Laminated Glossy Frontlit and Backlit PVC Flex Banners for your marketing needs. As a factory, we deliver exceptional value and impeccable service. Order now!

Tarpaulin900-Panama Weaving FR/UV/anti-mildew/easy cleaning surface

Shop the durable and versatile Tarpaulin900 from our factory. Made with FR/UV/anti-mildew properties, its easy cleaning surface ensures long-lasting protection.

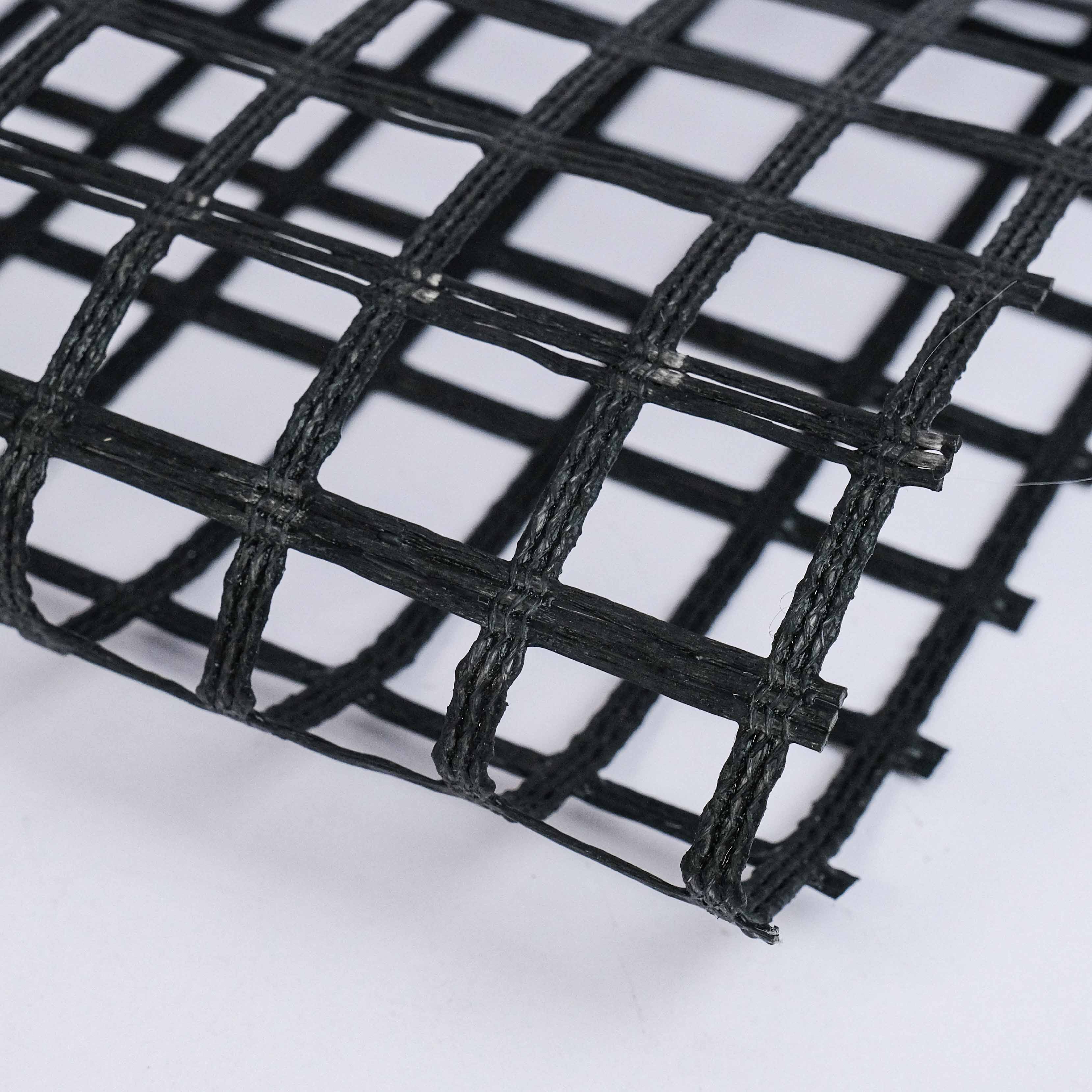

High Strength Polyester Geogrid PVC Coated For Soil Reinforcement And Foundation Stabilization

Get superior soil reinforcement and foundation stabilization with our high strength polyester geogrid PVC coated product. We are a trusted factory providing durable solutions.

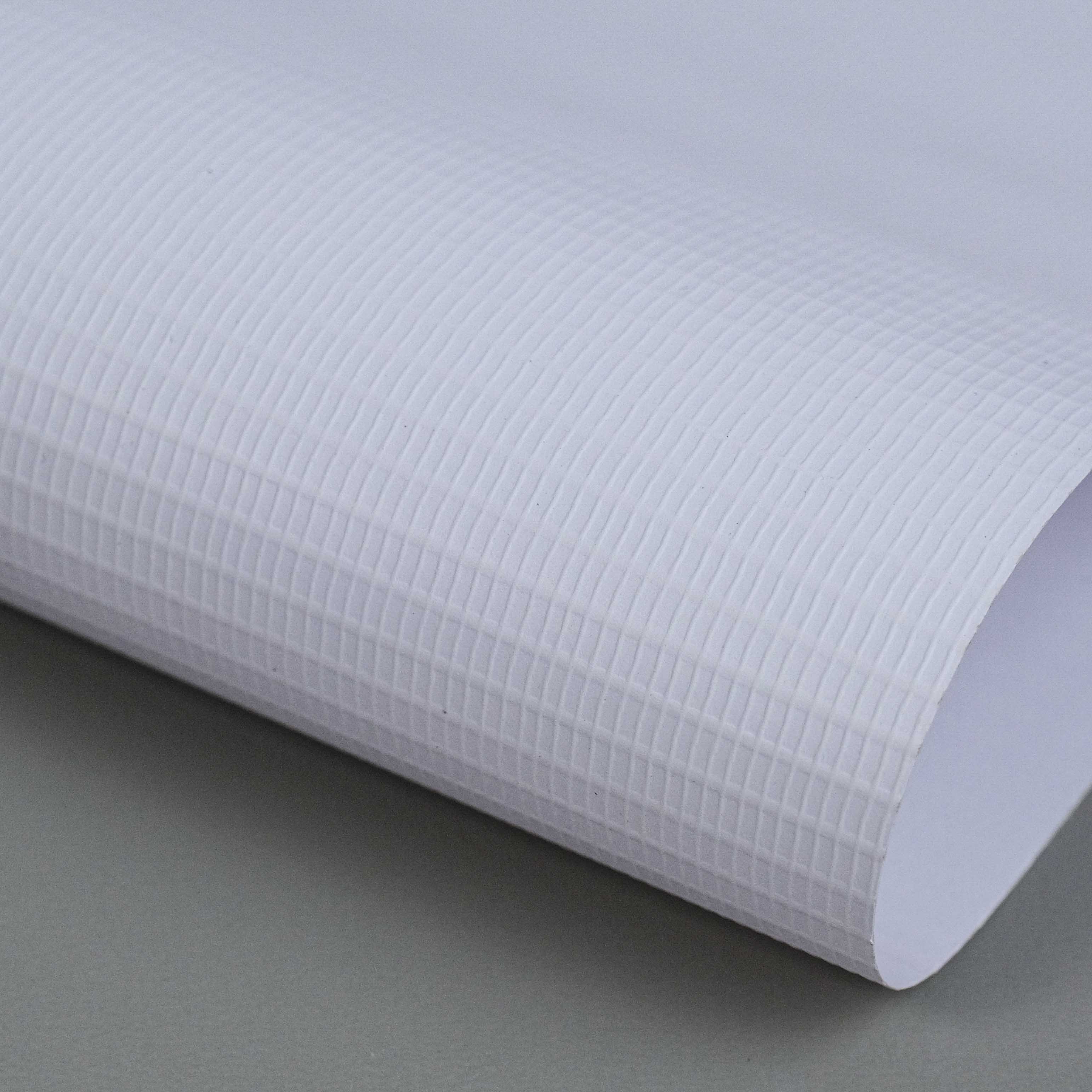

Tarpaulin680-Plain Weaving for tent fabrics and awning

Looking for high-quality tent fabrics and awning materials? Choose Tarpaulin680-Plain Weaving from our factory. Durable and reliable for all your outdoor needs.

18*12, 200*300D Laminated Glossy Frontlit Banner Roll For Panaflex Printing Printer Tarpaulin Outdoor Flex Lona Canvas

Get the best quality Laminated Glossy Frontlit Banner Roll for Panaflex Printing with our factory-made product. Ideal for outdoor flex and canvas printing.

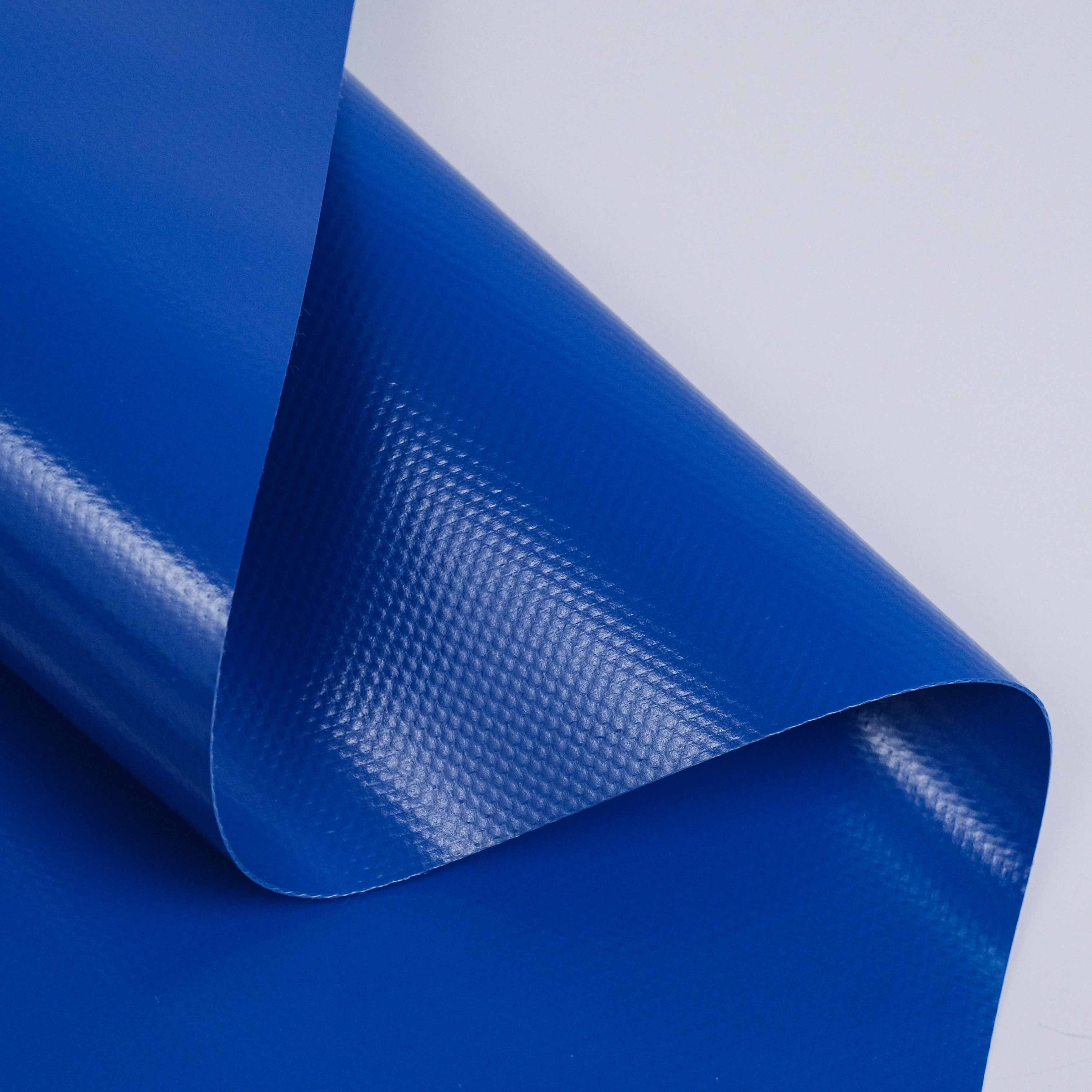

Tarpaulin630 Plain Weaving strong tensile strength for truck cover

Get high-quality Tarpaulin630 Plain Weaving truck covers with exceptional tensile strength. Trust our factory for durable and reliable products. Order now!

Outdoor Indoor Coated Mesh Fabric Vinyl For Printing And Advertising

Shop our high-quality outdoor and indoor coated mesh fabric vinyl for printing and advertising needs. We are a reputable factory offering durable and customizable options.

Colorful PVC Coated Mesh for fencing outdoor and indoor usage

Enhance the aesthetics of your outdoor and indoor spaces with our Colorful PVC Coated Mesh for fencing. Proudly manufactured by our factory for durable and versatile usage.

18*12, 200*300D Laminated Glossy Frontlit Banner

Factory direct 18*12 and 200*300D Laminated Glossy Frontlit Banners. High-quality, durable materials for impactful displays. Shop now!

Economical PVC Coated Mesh For Printing

Choose our economical PVC coated mesh for printing. We are a top-tier factory ensuring high quality and competitive prices. Boost your printing productivity today!

- Material Jetting: Leading Manufacturer and Exporter from China for Wholesale OEM Supply

- Reviews

- Related Videos

Introducing our revolutionary product, Material Jetting! As the name suggests, this cutting-edge technology allows for precise and efficient 3D printing by jetting materials onto a build platform layer by layer. With Material Jetting, we are bringing new possibilities to the world of manufacturing, design, and prototyping. In a traditional 3D printing process, layers of material are typically added one on top of the other. However, with Material Jetting, we have enhanced this process by utilizing jetting technology to deposit materials in an extremely precise and controlled manner. This ensures that each layer is accurately formed, resulting in high-quality, intricately designed objects. The versatility of Material Jetting is truly remarkable. It can work with a wide range of materials, including plastics, resins, and even metals. This opens up endless possibilities for industries such as automotive, aerospace, healthcare, and consumer goods. From manufacturing intricate parts for machinery to creating intricate jewelry designs, Material Jetting can do it all. One of the key advantages of Material Jetting is its ability to deliver exceptional surface finish and detail. This technology allows for the creation of complex geometries, intricate patterns, and fine features that were once unimaginable. The level of detail achieved is truly remarkable, making Material Jetting an ideal choice for applications that demand precision and aesthetics. Moreover, Material Jetting offers a faster production cycle compared to traditional manufacturing methods. With its high-speed jetting capabilities, it significantly reduces the time required to print complex designs. This means shorter lead times, improved time-to-market, and increased overall productivity. In conclusion, Material Jetting is revolutionizing the world of 3D printing. Its precision, versatility, and speed make it a game-changer for industries across the board. Experience the future of manufacturing and design with Material Jetting!

Material Jetting is a game-changer when it comes to designing and producing intricate 3D models. I recently got my hands on a material jetting 3D printer and I am amazed by the level of detail it offers. The technology works by precisely jetting layers of liquid resin onto a build platform, resulting in smooth and highly accurate models. The prints are incredibly precise, with intricate details and impressive surface finish. This technology allows for the creation of complex geometries that were once unimaginable. The only downside is the relatively high cost, but the quality and precision of the prints make it well worth the investment. Overall, material jetting is a cutting-edge technology that opens endless possibilities in product design and manufacturing.

Material Jetting is an absolute game-changer in the world of 3D printing. This technology utilizes high-resolution printers that precisely jet layers of liquid photopolymer materials onto a build tray, resulting in incredibly detailed and accurate prototypes. The level of precision achieved through Material Jetting is unmatched, making it an ideal choice for industries like aerospace, automotive, and medical. Its ability to print complex geometries and multi-material parts is truly impressive. Additionally, the final products exhibit excellent mechanical properties and surface finish. Although Material Jetting may come with a higher price tag, the quality and performance it delivers make it a worthwhile investment for anyone serious about pushing the boundaries of 3D printing.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours